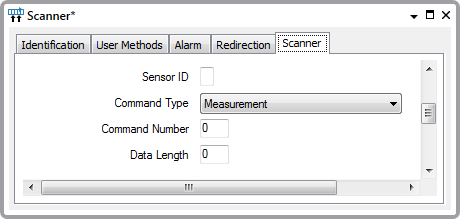

Use these fields on the Scanner tab of the SDI-12 Scanner Form to configure the sensor properties:

Specify the single-character device address that applies to the sensor that this scanner is to scan.

Sensors on an SDI-12 bus typically have addresses or IDs within the range 0 to 9. Some types of sensor also support the address ranges A to Z and/or a to z, for use on buses that have more than 10 sensors.

Use this combo box to specify the type of command that the scanner is to use in order to extract data from the sensor. Be aware that some sensors may not support all of the listed command types—see the documentation supplied with the sensor for information on the command types that the sensor supports.

Choose from:

The scanner issues a ‘Start Measurement’ command to the sensor, followed by one or more ‘Send Data’ commands, in order to retrieve the required number of measurements from the sensor.

The sensor may enforce a delay before the scanner can send its first ‘Send Data’ message. This is determined by the sensor’s response to the scanner’s ‘Start Measurement’ command.

This command is similar to the Measurement command above, but with an additional cyclic redundancy check (CRC) number. The sensor appends a CRC number to each reply that it sends in response to a ‘Send Data’ command. The CRC number relates to the data that is included in the transmission. The driver decodes the number to verify that the data received from the sensor is valid (has not become corrupted during transfer).

The sensor may enforce a delay before the scanner can send its first ‘Send Data’ message. This is determined by the sensor’s response to the scanner’s ‘Start Measurement and Request CRC’ command.

To retrieve the required number of measurements from the sensor, the scanner issues a ‘Start Concurrent Measurement’ command to the sensor, followed by one or more ‘Send Data’ commands.

The sensor may enforce a delay before the scanner can send its first ‘Send Data’ message. This is determined by the sensor’s response to the scanner’s ‘Start Concurrent Measurement’ command.

This command is similar to the ConcurrentMeasurement command above, but with an additional cyclic redundancy check (CRC) number. The sensor appends a CRC number to each reply that it sends in response to a ‘Send Data’ command. The number relates to the data that is included in the transmission. The driver decodes the number to verify that the data received from the sensor is valid (has not become corrupted during transfer).

The sensor may enforce a delay before the scanner can send its first ‘Send Data’ message. This is determined by the sensor’s response to the scanner’s ‘Start Concurrent Measurement and Request CRC’ command.

The scanner issues a ‘Continuous Measurements’ command to the sensor. The sensor immediately returns any measurements to the scanner, in response to this command.

This command is similar to the ContinuousMeasurements command above, but with an additional cyclic redundancy check (CRC) number. The sensor appends a CRC number to the reply that it sends to the scanner. The number relates to the data that is included in the transmission. The driver decodes the number to verify that the data received from the sensor is valid (has not become corrupted during transfer).

The scanner issues a ‘Start Verification’ command to the sensor, followed by one or more ‘Send Data’ commands, in order to retrieve the required number of measurements from the sensor.

The sensor may enforce a delay between issuing the ‘Start Verification’ and ‘Send Data’ messages.

Verification data might include information such as ROM signatures, RAM test results, or the results of other diagnostics in the sensor.

Applicable if the Command Type is a command other than ‘Verification’. Use this field to specify the command number that the scanner is to use in order to extract data from the sensor. The command number and its functionality varies, depending on the type of sensor from which the scanner is to extract data.

Refer to the documentation provided with the sensor for further information, and then specify the required command number, in the range 0 to 9.

Use to specify the maximum number of measurements that the sensor is to take in response to each command from this scanner. Use this property to reduce the communications overhead should the scanner only be required to retrieve some, but not all, of a sensor’s measurement readings.

Example:

An SDI-12 Scanner includes this configuration:

Command Type:Measurement

Data Length:5

The sensor that the scanner is scanning can return up to 9 measurement readings in response to each Measurement command. However, in this particular case, the scanner is only required to retrieve the first 5 readings, and hence the Data Length is set to 5. This reduces the communications overhead, as multiple ‘Send Data’ messages might otherwise have been required to retrieve all 9 readings.

The maximum number of measurements that a sensor can make in response to a command varies, depending on the type of sensor and the Command Type. Refer to the documentation provided with the sensor for information on how many measurement readings the sensor can make and the order in which it takes those readings. The maximum number of readings that can be specified in this field are listed below:

| Command Type | Maximum Data Length |

|---|---|

Measurement/Measurement with CRC | 9* |

Concurrent Measurement/Concurrent Measurement with CRC | 99* |

Continuous Measurements/Continuous Measurements with CRC | Varies, depending on the sensor |

Verification | 9* |

* Be aware that this value may be further limited by the type of sensor and the number of measurements that it can take.

For each measurement that a scanner is to extract, a corresponding SDI-12 Analog Point needs to exist in the Geo SCADA Expert database (see Configuring an SDI-12 Analog Point). Each point has to be associated with the relevant SDI-12 Scanner. (Should more points be associated with a particular scanner than are specified in that scanner’s Data Length field, a ‘Point does not fall within range of scanner’ message will be displayed at the bottom of the Point Form.)