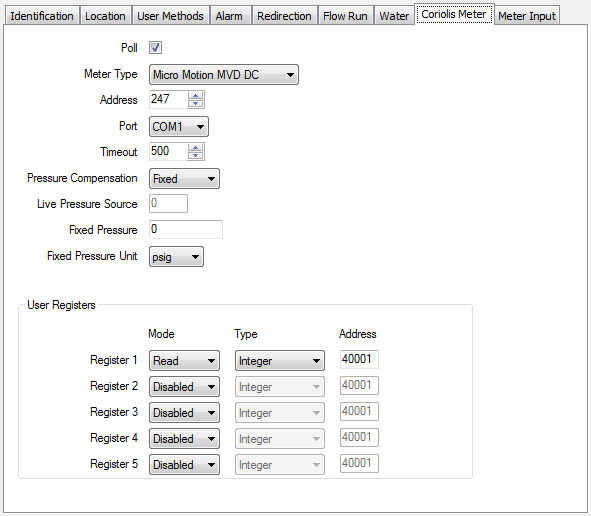

Geo SCADA Expert provides you with the facility to configure connections to a Coriolis meter. Use the properties on the Coriolis Meter tab display to configure the connection properties.

You can configure these properties directly in Geo SCADA Expert, or read the configuration into the Geo SCADA Expert database (see Configure or Read the Flow Run Configuration).

Poll

Use the check box to specify whether the Coriolis Meter is polled for data. Select the check box for the Realflo driver to poll the Coriolis meter; clear the check box if polling is not required.

Meter Type

Use the combo box to specify the type of Coriolis Meter being used. Choose one of the following:

- Endress & Hauser Promass 83 Coriolis Meter (E&H Promass 83)

- Foxboro CFT51 or NOCT60 Coriolis Meter (Foxboro CFT51/NOCT60) (NOCT60 is supported by Realflo version 6.93 onwards)

- Emerson Micro Motion 2700MVD Coriolis Meter (Micro Motion 2700MVD)

- Emerson Micro Motion MVD Direct Connect Coriolis Meter (Micro Motion MVD DC)

- Endress & Hauser Proline Promass 100 Coriolis Meter (E&H Promass 100) (supported by Realflo version 6.95 onwards).

Address

Enter the Modbus Address of the Coriolis Meter. Each Coriolis meter this is using the same serial port on the flow computer needs to have a unique Modbus address. Valid Modbus addresses are from 1 and 255 inclusive. The default address is 247.

Port

Enter the communication Port on the flow computer that is used to communicate with the Coriolis meter. Valid port selections depend on the type of controller on which the flow computer is running. The default port is the first valid port that is available on the controller. You can allocate multiple devices to a port, but the number and type are limited by the Timeout time.

Timeout

Enter the time that the flow computer will wait for a response to Modbus read commands sent to the Coriolis meter by the flow computer. If the timeout time is exceeded, the command is deemed unsuccessful. Valid timeout values are from 1 to 1000 ms inclusive. The default value is 500 ms.

Entering a timeout value under 250 ms might not provide sufficient time for a response to occur. Refer to the Coriolis meter documentation for the polling time of each meter type. The total time to poll (or update) all the devices on a port should not exceed 1000 milliseconds.

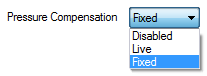

Pressure Compensation

With Realflo version 6.95 onwards, use the combo box to specify the type of pressure compensation being used for the Coriolis meter.

Choose from:

- Disabled—No pressure compensation is performed. The fields immediately following are disabled and unavailable for use.

- Live—The pressure compensation value is derived from the Live Pressure Source (see below).

- Fixed—The pressure compensation uses a Fixed Pressure value (see below).

INACCURATE FLOW MEASUREMENT

With Realflo versions 6.93 and 6.94, use the combo box to enable or disable the use of pressure compensation for the Foxboro CFT51/NOC60 type Coriolis meter. The function is not available for other meter types.

Live Pressure Source

This field only applies when the Pressure Compensation is set to 'Live'. Use the field to indicate the number of the Flow Run from which the Pressure Compensation value is derived.

Fixed Pressure

This field only applies when the Pressure Compensation is set to 'Fixed'. Use the field to specify the fixed value that is to be used for the Pressure Compensation.

Fixed Pressure Unit

This combo box only applies when the Pressure Compensation is set to 'Fixed'. Use the combo box to select the units in which the Fixed Pressure value is entered.

Choose from:

- KPag (Kilopascal gauge)

- psig (pounds per square inch gauge).

Register 1-5

Use this section to configure up to five custom data registers for the meter. For each register you require, configure the following properties:

Mode

Use the combo box to configure the register mode to Read or Write.

Type

Use the combo box to define the format of the Modbus register in the Coriolis meter.

- Integer (default)

- Long Integer

- Float

- Coil

- Status

Address

Specify a Modbus register address for each register that you are configuring. The default value is 40001. The valid ranges are: 00001 to 09999, 10001 to 19999, 30001 to 39999 and 40001 to 49999 inclusive.

When selecting an address you need to consider the register Type selected:

- Integer ( valid registers 30001 to 39999 and 40001 to 49999 inclusive)

- Long Integer ( valid registers 30001 to 39999 and 40001 to 49999 inclusive)

- Float ( valid registers 30001 to 39999 and 40001 to 49999 inclusive)

- Coil ( valid registers 00001 and 09999)

- Status ( valid registers 10001 and 19999)

Further Information

For more detailed information on these properties, see the documentation provided with the Realflo application.